At Hims & Hers, we’re committed to providing safe, high-quality personalized care. From the treatments we develop to the experience we offer, advancing a culture of quality and safety is at the heart of everything we do. Our commitment to responsibility starts with top medical experts, follows strict standards, and operates with uncompromising regulatory compliance—raising the bar for the experience customers can expect throughout their health journeys.

01 Delivering access to trusted care with qualified and expert teams

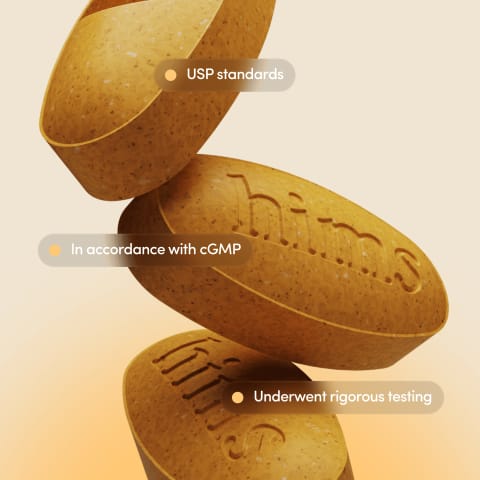

Our commitment to quality and safety begins with our team. Pharmacists and technicians involved in compounding are trusted experts at the core of our model. As a best-in-class workforce, they undergo rigorous and ongoing training in aseptic technique, process validation, hazardous drug handling, and other critical practices. We require continuing education, qualification assessments, and adherence to applicable Food and Drug Administration (FDA) and state pharmacy requirements, including US Pharmacopoeia (USP) standards and applicable current good manufacturing practices (cGMP) requirements. By investing in our team’s development and expertise, we ensure that every step of care is grounded in professionalism, precision, and trust.

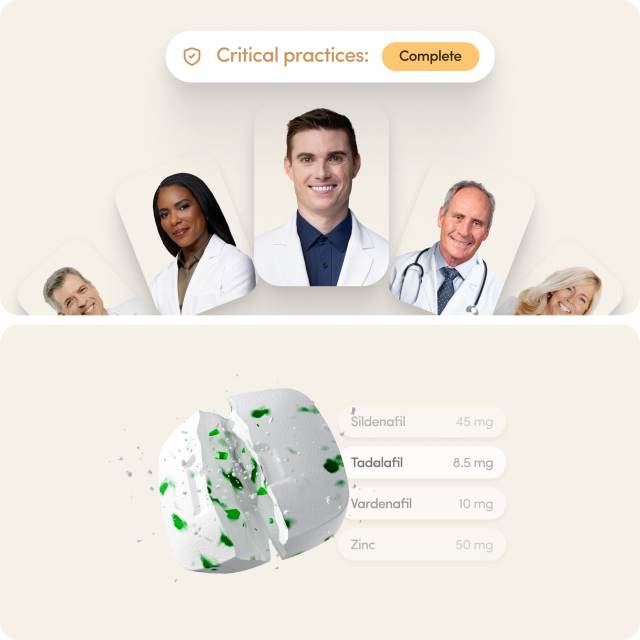

02 Sourcing pharmaceutical-grade ingredients to ensure purity and potency

We require that all active pharmaceutical ingredients (APIs) used in compounded medications available through our platform be sourced from FDA-registered facilities and accompanied by Certificates of Analysis (COAs) to confirm identity, potency, and purity. Ingredients must meet relevant USP standards and applicable state board regulations and have been manufactured in accordance with cGMP, as applicable. All raw materials, particularly APIs, undergo rigorous testing for potency, identity, and acceptability using validated analytical methods. This approach upholds product integrity and ensures alignment with regulatory and quality standards from the outset.

03 Adhering to cGMP, USP, and regulatory standards

We require that all sterile, non-sterile, and hazardous compounding processes follow all relevant regulatory requirements, including USP standards and, in the case of any outsourcing facility, applicable cGMP, supported by documentation. We also follow applicable state pharmacy board requirements and FDA guidance.

04 Maintaining controlled environments & facility standards

We require that all sterile compounding take place in cleanroom and controlled environments that meet relevant regulatory requirements, including USP standards, and in the case of any outsourcing facility, applicable cGMP. This includes HEPA filtration, environmental monitoring, and fully validated aseptic processing areas. For both sterile and non-sterile products, we apply beyond-use dating (BUD) based on stability studies and USP standards to ensure appropriate shelf life and safety.

05 Implementing testing protocols and quality controls for sterile compounding

We require that all sterile compounded products undergo routine potency and sterility testing in accordance with applicable USP standards, using risk-based protocols and batch verification to support compliance and patient safety. As appropriate, mandatory lot release testing—including sterility, endotoxin, and particulate matter testing—is conducted prior to distribution, with full documentation, quarantine procedures, and FDA-audited quality assurance systems.

06 Documenting compounding processes and ensuring label accuracy

We require that medication labels comply with applicable FDA requirements and state pharmacy board requirements and, as applicable, include such information as active ingredients, concentration, lot or batch numbers, beyond-use date (BUD), and storage conditions to support traceability and distribution. We maintain documentation of compounding processes, including formula validation, weighing logs, and technician sign-offs.

07 Maintaining ethical practices and transparent communications

We require adherence to applicable marketing and promotional regulations. Communications must include appropriate disclosures and risk information to help customers understand the nature of compounded medications, including that FDA does not approve compounded drugs or evaluate them for safety or efficacy. This commitment reflects our focus on transparency, ethical conduct, and consumer trust.

08 Monitoring adverse events, handling complaints, and managing recalls

We maintain FDA-compliant pharmacovigilance programs, as applicable, that require timely reporting of adverse events and rapid recall protocols when necessary. We also have formal complaint handling procedures in place to document, investigate, and resolve product-related concerns. In the event of a recall, we ensure prompt notification to regulatory authorities, patients, and providers regarding any affected lots, in alignment with applicable reporting requirements and patient safety protocols.

09 Committing to safe handling, storage, and disposal practices

We strive to meet all applicable environmental, cGMP, and USP standards for the handling, storage, and disposal of hazardous materials and controlled substances. This includes validated cleaning protocols, secure disposal methods, and safeguards designed to protect both staff and patients. We are committed to using proper disposal practices to prevent environmental contamination and to align with all relevant regulatory expectations.

10 Implementing quality assurance initiatives for operational excellence

We are committed to implementing robust Quality Assurance programs that foster continuous improvement and operational excellence. These include regular internal audits, proactive process improvement initiatives, and timely updates based on evolving USP standards and appropriate FDA protocols. Where relevant and appropriate, we incorporate Corrective and Preventive Action (CAPA) procedures and maintain alignment with cGMP reflected in FDA guidance and inspection findings, and industry best practices to strengthen our systems and improve care delivery.